Initiatives for social issue | Machine vibration measurement and analysis

Machine vibration measurement and analysis

The importance of predictive maintenance and preventive maintenance, which performs appropriate maintenance by predicting and monitoring equipment failure, damage, deterioration, etc., is getting increase.

Epson's vibration sensors are contributing to the calculation of appropriate maintenance timing for equipment such as large motors.

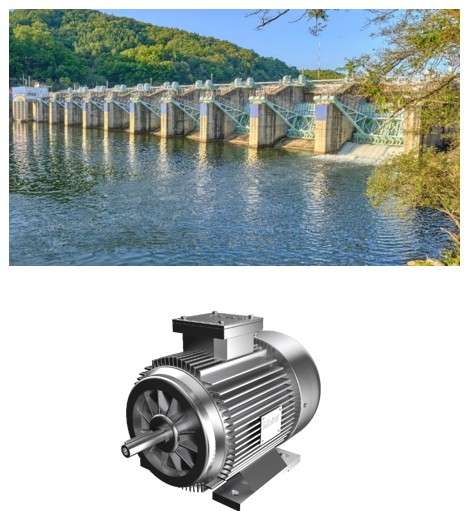

- Reduction of environmental load

EPSON vibration sensor contributes to stable operation of renewable energy facilities through

appropriate maintenance by measuring vibrations of large motors that open and close water gates.

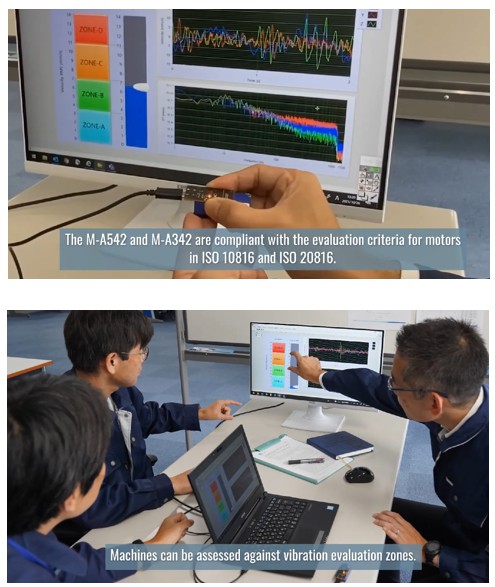

- Improving the working environment

EPSON vibration sensor makes it possible to achieve more efficient facility management and extend

its maintenance cycle.

Value proposition

- ISO 10816 and ISO 20816 compliant

Support velocity and displacement output

(The sensor can support velocity and

displacement output)

- Wide output range

No need to adjust the measurement range to match the magnitude of vibration (It can

precisely measure vibration without any adjustment regardless of vibration intensity at

the range of measurement frequency)

- Strong to magnetic fields

It can accurately measure vibration from motors with strong magnetic field.

- Resistant to noise

Digital output has an ability to resist the effects of noise

- Simple measurement environment

No charge amp, A/D converter or other peripheral equipment needed(It is used without

charge amp, A/D converter and other peripheral equipment)

In other places like these

- Waste disposal plants and Wind turbines

equipped with large motors

Products lineup

For details of each product. Link